Quality Management

Taizhou Wubiao Machinery Co., Ltd. passed the TS16949 quality system certification at the beginning of its establishment, and passed the IATF16949 version change certification last year.

Blessed with years of experience in the design, manufacturing, and control of fasteners, the technology/quality departments ensure precise product design, optimized cost, and reasonable process arrangement with the help of five major tools, i.e. Measuring System Analysis (MSA), Advanced Product Quality Planning (APQP), Statistic Process Control (SPC), Failure Modes and Effects Analysis (FMEA), and Production Part Approval Procedure (PPAP).

The inspection department divides the inspection process into Inbound Process Check (IPC), Process Quality Check (PQC), and Final Quality Check (FQC). Employees are educated on inspection tools, trained on inspection capabilities, and inculcated with a sense of quality, so that everyone values quality, acts on quality, and competes with quality.

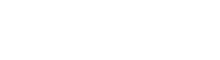

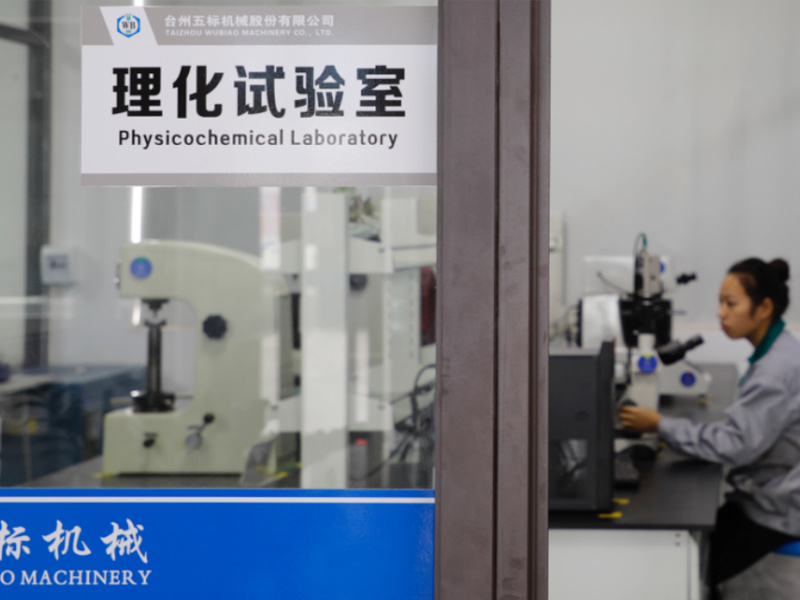

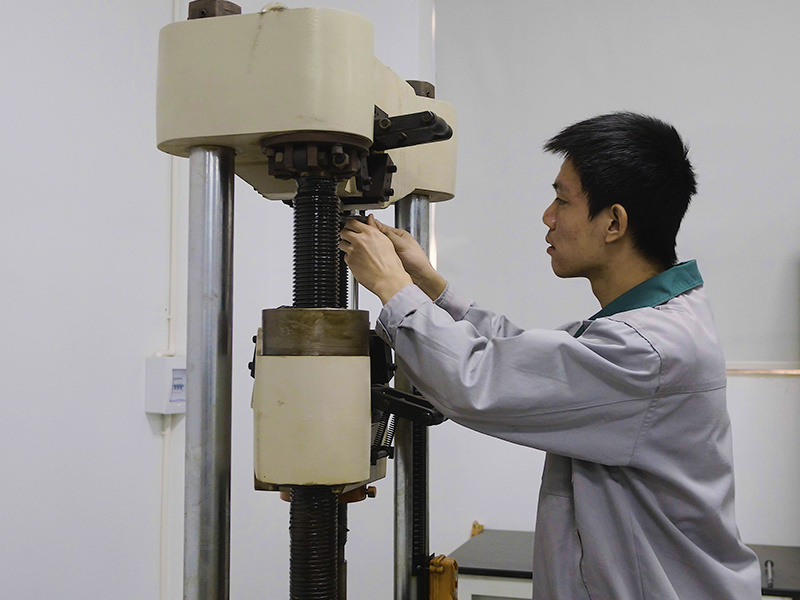

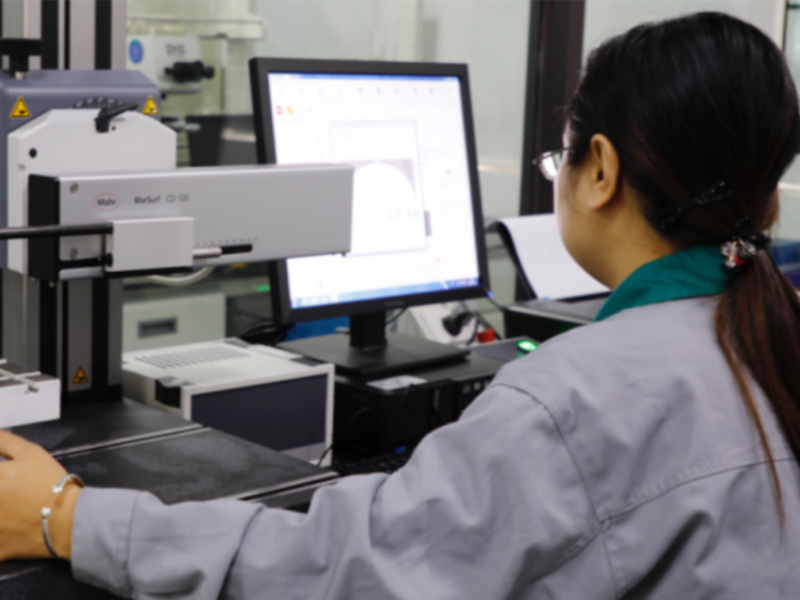

Our self-owned laboratory has introduced SPECTRO spectrum analyzer, Mahr profiler, Mitutoyo roughness tester, and a dozen of imported/domestic testing equipment. Moreover, laboratory facilities are classified into raw material testing, precision measurement, metallographic analysis, mechanical properties, and surface treatment tests. We rely on our own testing capability to measure all of our product lineups to ensure product conformity.

Warehouse

Metering room

Material Analysis Room

Production Comprehensive Office

Mold warehouse

Physical and chemical laboratory

Performance test room

Corner of the laboratory

Corner of the laboratory

Corner of the laboratory

Salt Spray Laboratory

Corner of the plant

Corner of the plant

Corner of the plant

Corner of the plant

Corner of the plant

Corner of the plant